Why nuclear companies benefit from working with OMS

OMS has a proven track record in giving customers trusted metrology information about their assets. In 2004, OMS was founded on the basis of pioneering pipe inspection technology. Since then, we have measured over one million pipes from two inches to 120 inches and scanned over 250,000 welds. Over the past five years we have invested heavily in our R&D team and specifically its robotic capabilities. Now – OMS can conduct our world-leading inspection in ever-more challenging locations, leveraging these advancements in robotic crawler systems.

Marcus Smiles, Global Manager – Energy & New Business, said, “Our customers in the nuclear sector are really benefiting from our cumulative years of experience in other sectors – in particular our advanced internal laser profilometry combined with high-definition visual testing has been really valuable. For example, to understand and measure surfaces before and after internal grinding activities and to quantify the amount of material removed.”

Laser metrology experts with over 20 years’ experience

As a world-leading independent inspection and remediation company, OMS has been using state-of-the-art laser systems to measure assets for over 20 years. During that time, we have measured over one million pipes and scanned over 250,000 welds, providing comprehensive data to our clients that helps them solve issues at an early stage and make rapid decisions in the field – ultimately to save time and money, and improve safety and quality. With a long track record of quality work in the oil and gas sector, OMS has recently completed several successful projects in nuclear energy and has several more coming down the line.

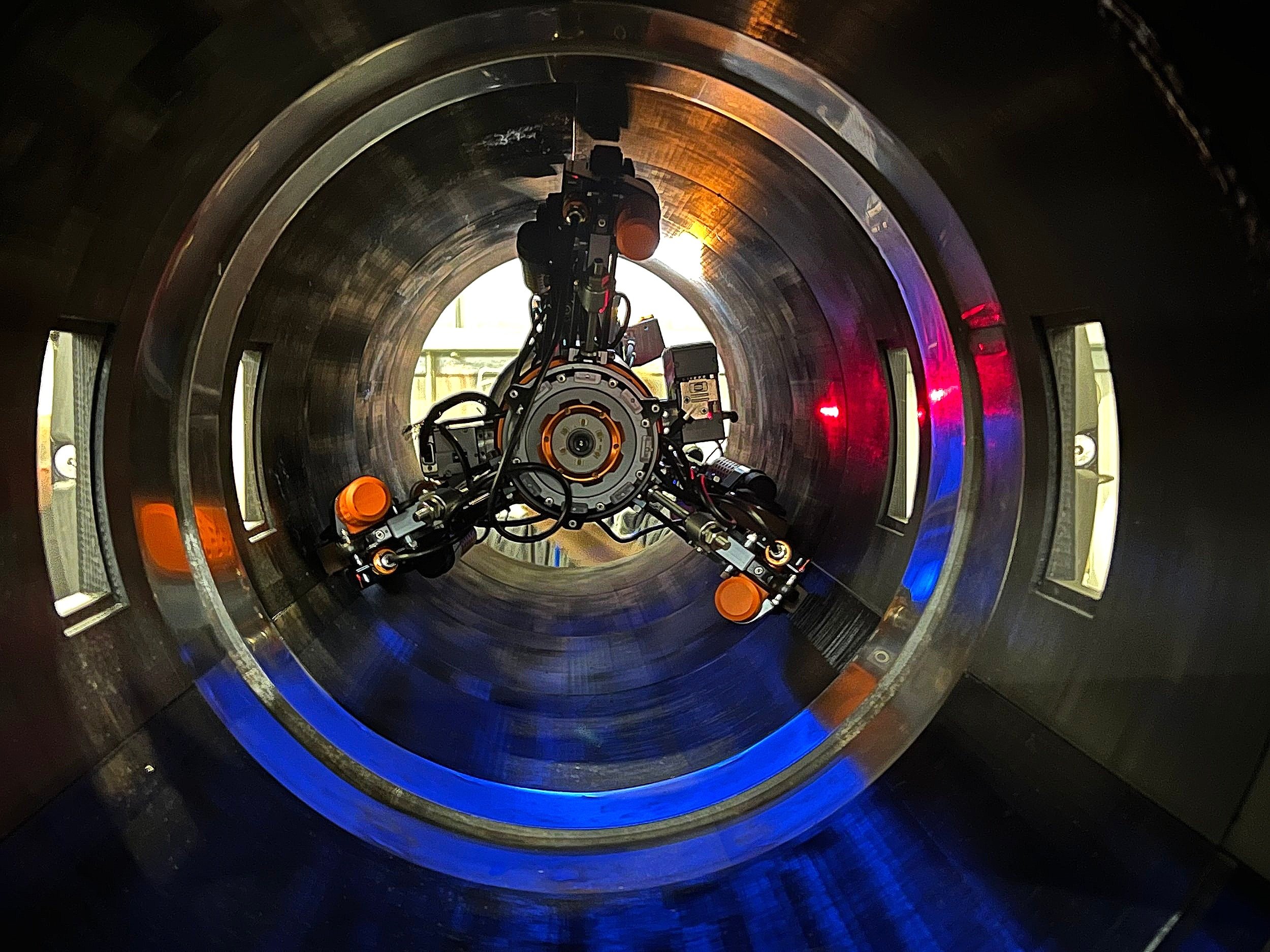

Crawler in pipe

Why work with OMS?

OMS is ideally placed to work with nuclear clients on challenging problems. Our extensive experience in oil and gas makes us a practical partner for clients looking to solve difficult issues. OMS technology, services and operators have deployed on many of the most significant energy projects of the last 20 years. Our team fully understands the difficulties of hazardous energy extraction environments, where focus on safety is paramount. We have helped clients comply with the strictest of project criteria and safety requirements, providing increased efficiency without compromising in any area. Our team and equipment deploy rapidly, arriving on location fully equipped and ready to deal with challenging situations. Expertise we have gained in oil and gas work is directly transferable to nuclear power and other clean energy environments.

Nuclear success

During the last few years, OMS has completed several successful nuclear energy projects, building strong relationships with our clients in the nuclear EPC sector and with top power plant operators. These have included assisting with the removal and replacement of some pipework in a primary circuit, a challenging project involving many service providers. We have developed specific AGILITY robotic crawlers capable of achieving our industry-leading visual and laser profilometry in complex pipework across a range of pipe diameters and ID ranges. Our technology has been fully qualified for nuclear environments and is remotely operated, thus increasing safety by removing any requirement for man-entry.

Nuclear AGILITY.micro crawler

We have developed collaborative working relationships with clients and other nuclear industry service providers where we can focus on improving technology, safety and efficiency – sharing knowledge and experience that will benefit both the industry and the environment in the long-term.

Focus on R&D

OMS founder, Dr Tim Clarke FInstPhys., is a hugely skilled innovator whose proactive attitude to solving problems for clients permeates the entire business. Since 2007 we have won three Queen’s Awards (now King’s Awards) for Innovation, highly prestigious accolades achieved by only the best in the business. We have a collaborative and customer-focused mindset that benefits our clients. We approach projects with our customers’ needs at the forefront of our minds – frequently adapting and modifying our technology so that it better meets client requirements – and often developing systems completely from scratch. This focus on clients’ needs has meant we have sometimes been able to provide solutions for problems before being asked.

Our well-resourced and highly skilled R&D department has extensive experience of solving difficult issues. They are an approachable and friendly team, working alongside clients to create optimum solutions to challenging problems.

Crawler in development

Agile deployment – rapid response to any situation

The OMS team can respond quickly to a problem. Our clients in oil and gas have always appreciated our ability to arrive rapidly at a project, especially when something has gone wrong and a quick response is essential. OMS equipment, such as our AGILITY robotic crawlers, is lightweight and easily portable, transported in suitcases or even carry-on luggage. We have a skilled team of international operators and a responsive head office, with proactive project managers capable of handling any situation.

Nuclear AGILITY.mini crawler

Challenging nuclear problem? We may be able to help

OMS has vast experience helping clients in both traditional and clean energy solve problems. Our laser measurement and inspection technology is ideally adapted for nuclear energy and our focus on resolving issues while maintaining stringent standards and strict safety requirements is unrivalled. The OMS team is easy to work with, our collaborative and friendly approach is appreciated by all our clients. If you have a thorny issue, we may be able to help. Contact us.

Published 31.03.25

(5 minute read)

By Marcus Smiles, Global Manager